Cryogenic tanks

In accordance with the strategy of continuous development of the company, as a result of research and development work carried out and thanks to the support from European Funds, Promostal has introduced a series of types of stationary vertical and horizontal cryogenic tanks to its offer intended for the storage of LNG, nitrogen, oxygen, carbon dioxide, argon with the following parameters:

In accordance with the strategy of continuous development of the company, as a result of research and development work carried out and thanks to the support from European Funds, Promostal has introduced a series of types of stationary vertical and horizontal cryogenic tanks to its offer intended for the storage of LNG, nitrogen, oxygen, carbon dioxide, argon with the following parameters:

- capacity from 30 to 100 m3,

- maximum permissible working pressure MAWP: 11 bar,

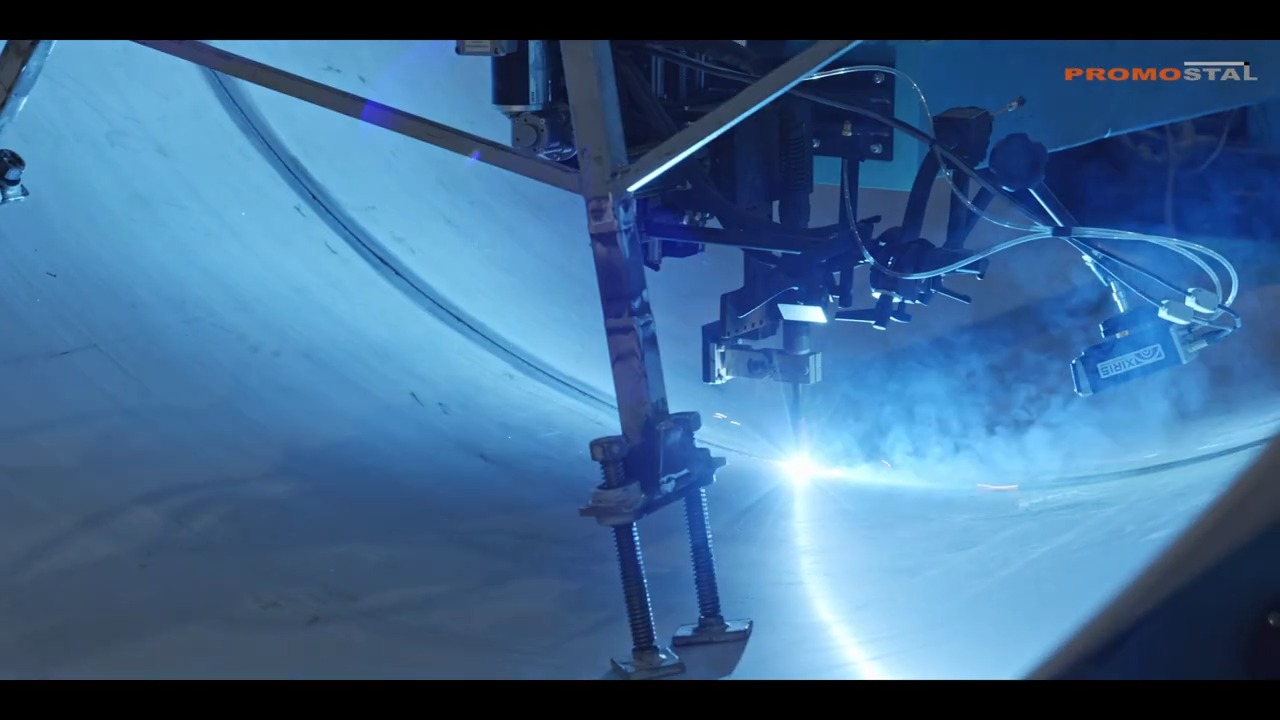

- construction: double-walled tank with vacuum insulation and multilayer insulation,

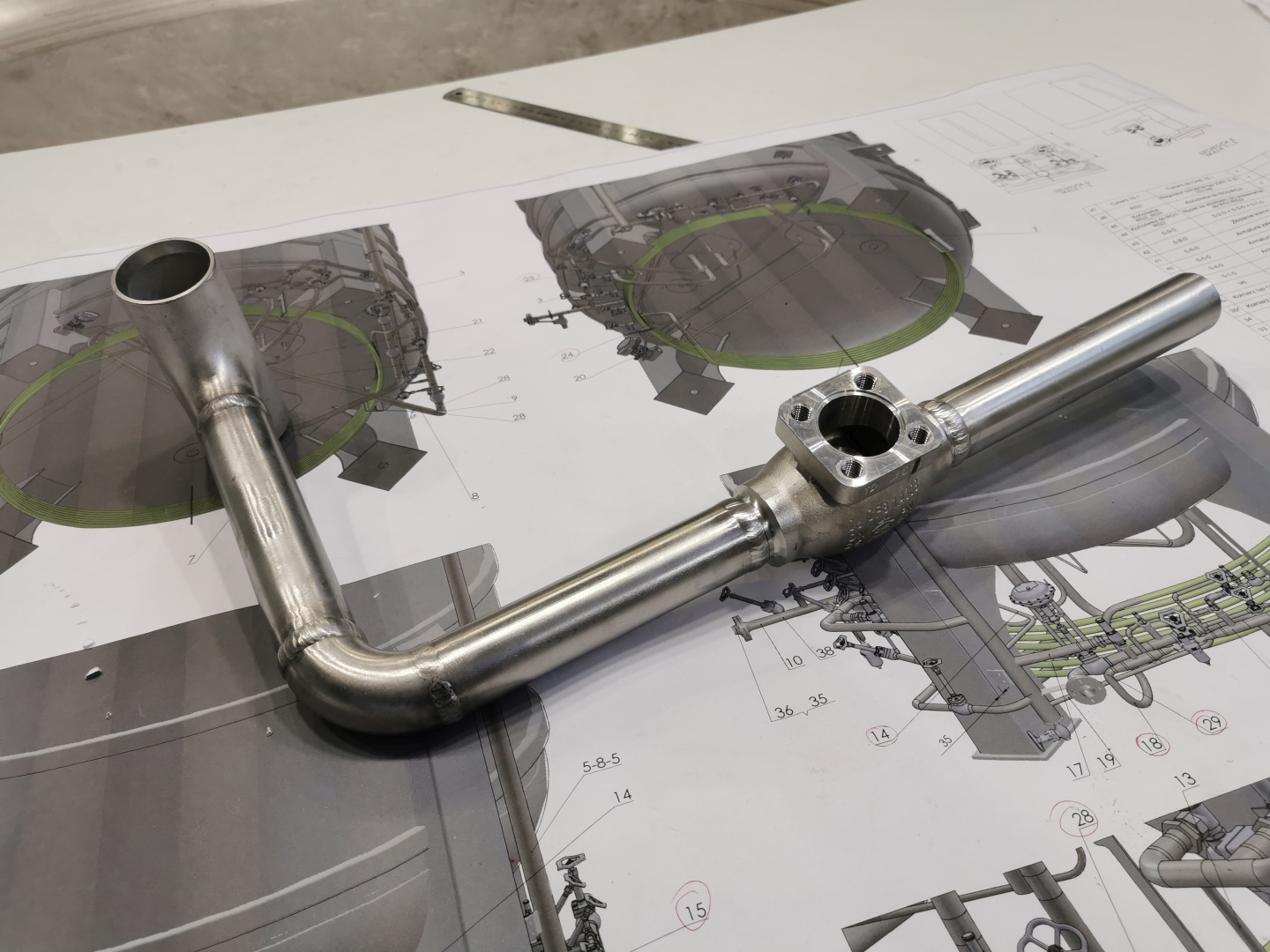

- internal tank, piping and fittings made of high-alloy steel,

- maximum filling – 95%,

- allowable min./max. temperature: -196ºC/+50ºC (internal tank), -40ºC/+50ºC (external tank),

- design in accordance with EN 13458 ,

- manufacture and CE certification in accordance with the PED 2014/68/EU directive by the UDT-CERT notified body, module B+F,

- the tank is made of 99% recyclable materials for recycling.

Cryogenic tanks produced by Promostal:

- have high insulation, and thus minimal gas loss during operation (they are distinguished by the MLI screen super-insulation used),

- have ~20% less weight thanks to the insulating materials used – this reduces installation costs,

- they do not lose their insulating properties during transport.

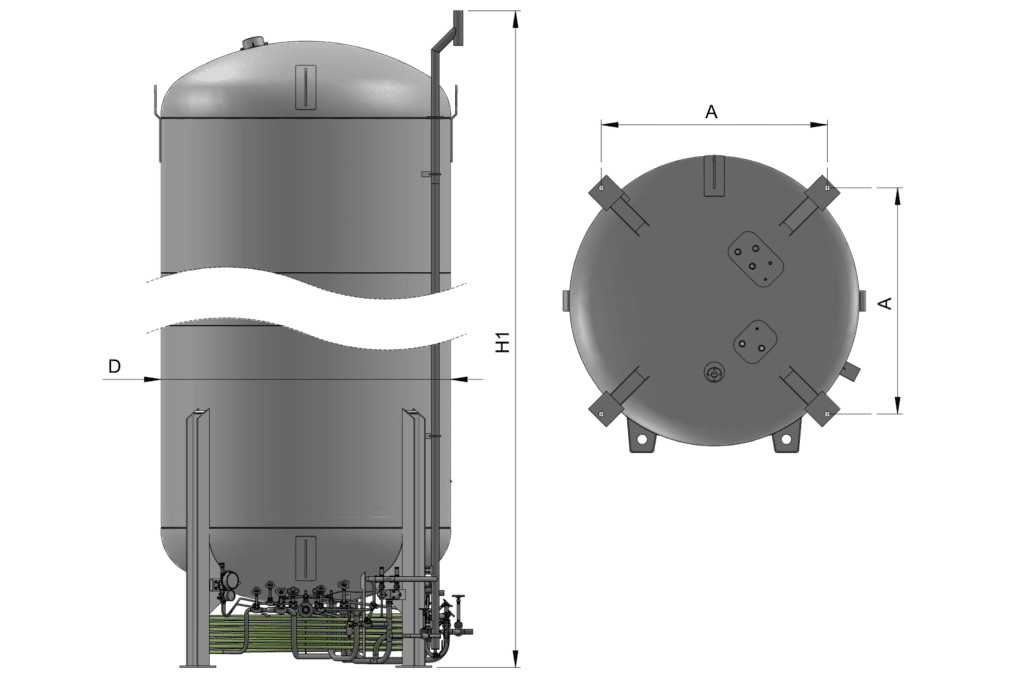

Vertical cryogenic tanks

| VERTICAL MODELS | DST-V30 | DST-V40 | DST-V50 | DST-V60 | DST-V80 | DST-V100 | |

|---|---|---|---|---|---|---|---|

| Gross capacity | m³ | 30.2 | 40.2 | 50.1 | 60.0 | 80.0 | 100.0 |

| Net capacity (95%) | m³ | 28.7 | 38.2 | 47.6 | 57.0 | 76.0 | 95.0 |

| Diameter D | mm | 3,000 | 3,000 | 3,000 | 3,000 | 3,500 | 3,500 |

| Height H1 | mm | 7,880 | 9,930 | 11,990 | 13,880 | 14,570 | 17,430 |

| Spread spacing A | mm | 2,224 | 2,224 | 2,224 | 2,224 | * | * |

| Tank weight | kg | 10,100 | 10,930 | 11,690 | 14,710 | 18,000 | 22,470 |

| Design pressure | bar | 11 | 11 | 11 | 11 | 11 | 11 |

* LNG tanks with a diameter of D = 3,500 mm are mounted on three supports. Exact dimensions to be agreed.

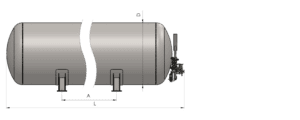

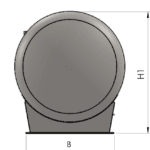

Horizontal cryogenic tanks

| HORIZONTAL MODELS | DST-H32 | DST-H60 | |

|---|---|---|---|

| Gross capacity | m³ | 32 | 60 |

| Net Capacity | m³ | 30.4 | 57 |

| Diameter D | mm | 2,500 | 3 00 |

| Height H1 | mm | 2,815 | 3,315 |

| Spread spacing A | mm | 7,000 | 8,850 |

| Support B dimensions | mm | 2,000 | 2,400 |

| Overall length L | mm | 11,890 | 14,825 |

| Design pressure | bar | 11 | 11 |